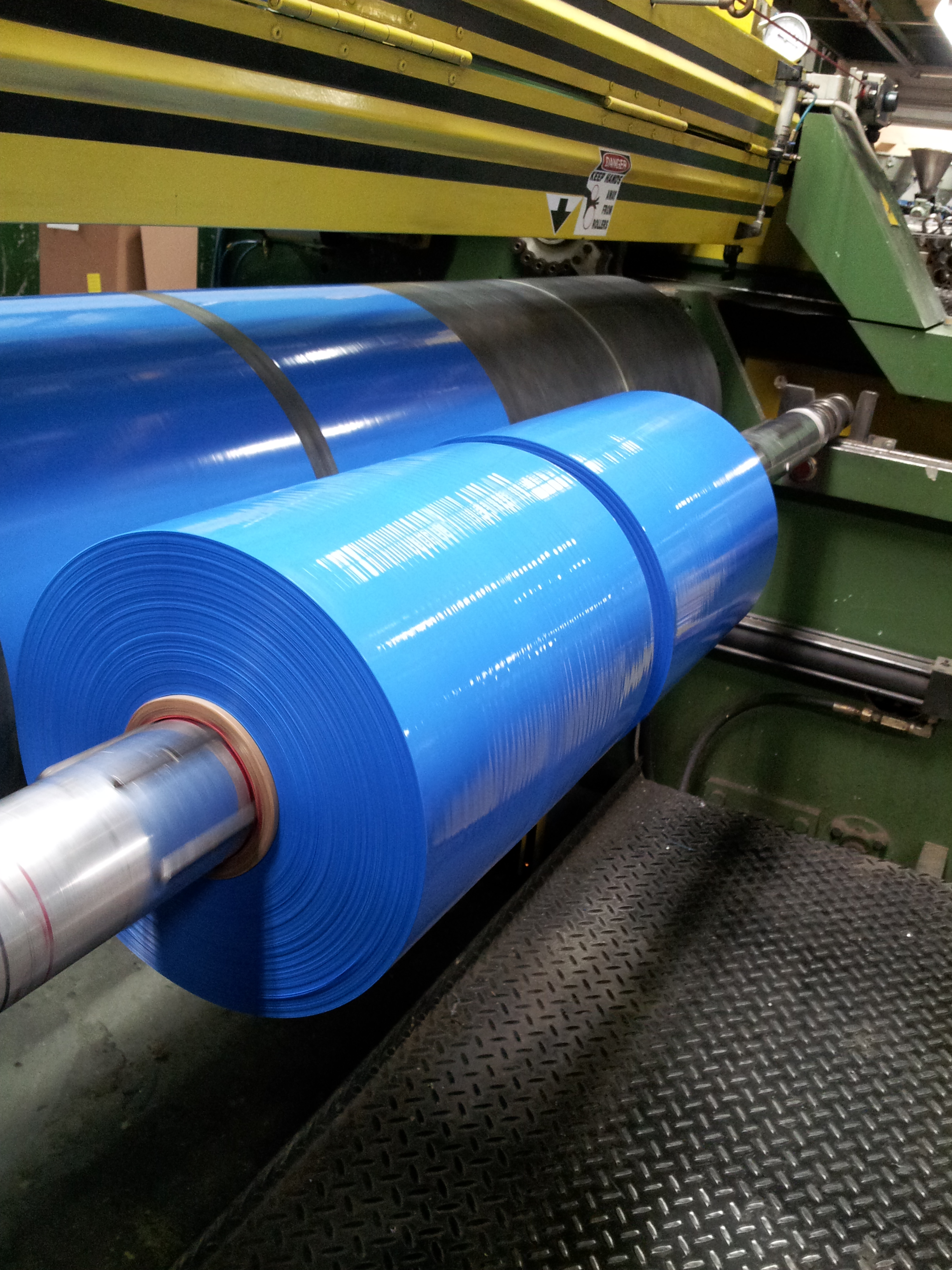

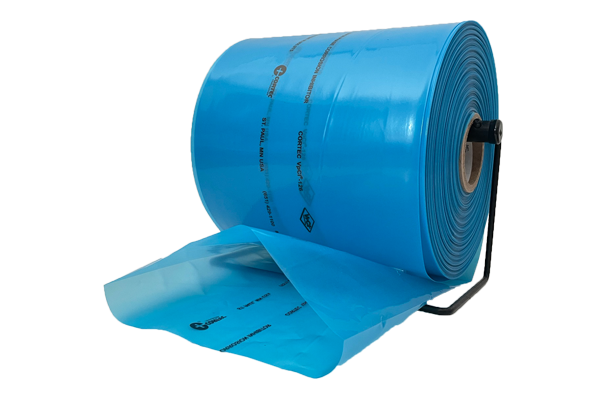

Cortec’s recyclable VpCI® plastic sheeting and bags are powerful, cost effective, and simple to use. They provide Total Corrosion Control for multiple metal types and come in many sizes and formats—from small Top-Seal Reclosable zip bags that protect nuts and bolts, to 30 foot (9.1 m) wide heavy duty sheeting for storing giant industrial equipment outdoors. Available formats include:

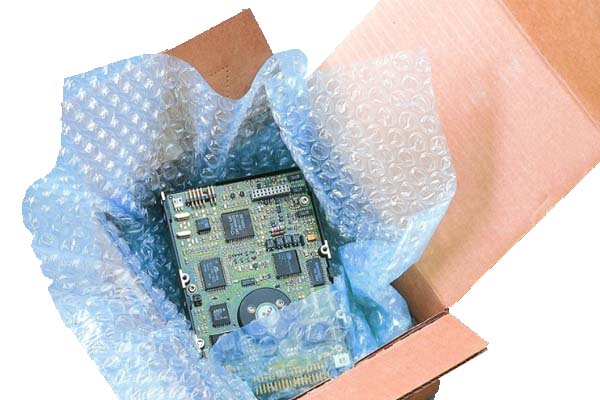

Simply wrap, shroud, or pack your products or equipment in VCI plastic films and bags for continuous protection during work in progress, storage, transit, export packaging, machinery preservation, lay-up, or mothballing.

VCI molecules in the anticorrosive plastic films and bags vaporize and then condense on metal surfaces in the enclosed package, forming an invisible molecular protective layer against the corrosive forces of salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. After the metal part is taken out of the package, the VCI molecules float away, and the metal components, machinery, or products are ready for immediate use, no cleaning or degreasing required.

We provide VCI plastic films and bags that are exceptional for protection of large equipment for export shipping, stretch wrapping of steel coils, packaging of highly sensitive electronic components, shrink wrapping of new vehicles and equipment, lining containers for overseas shipments of multiple items, and packaging of small parts in zipper closure bags. VCI films and bags replace conventional rust preventatives such as oils and desiccants, allowing users to save time, hassle, and labor costs by eliminating the degreasing or coating removal required in the past. Using the right VCI plastic film will ensure your valued assets are clean, dry, corrosion free, and ready to use when they are unpacked.