We offer recyclable VCI plastic sheeting and bags that come in many sizes and shapes. From small top-seal bags that protect nuts and bolts, to 30 foot (9.1 m) wide heavy duty sheeting for storing giant industrial equipment outdoors.

We make available coated papers that are recyclable and fully-repulpable which provide corrosion protection options in widths nearing 100 inches for large single item packaging, parts or any other metal surface that requires corrosion protection.

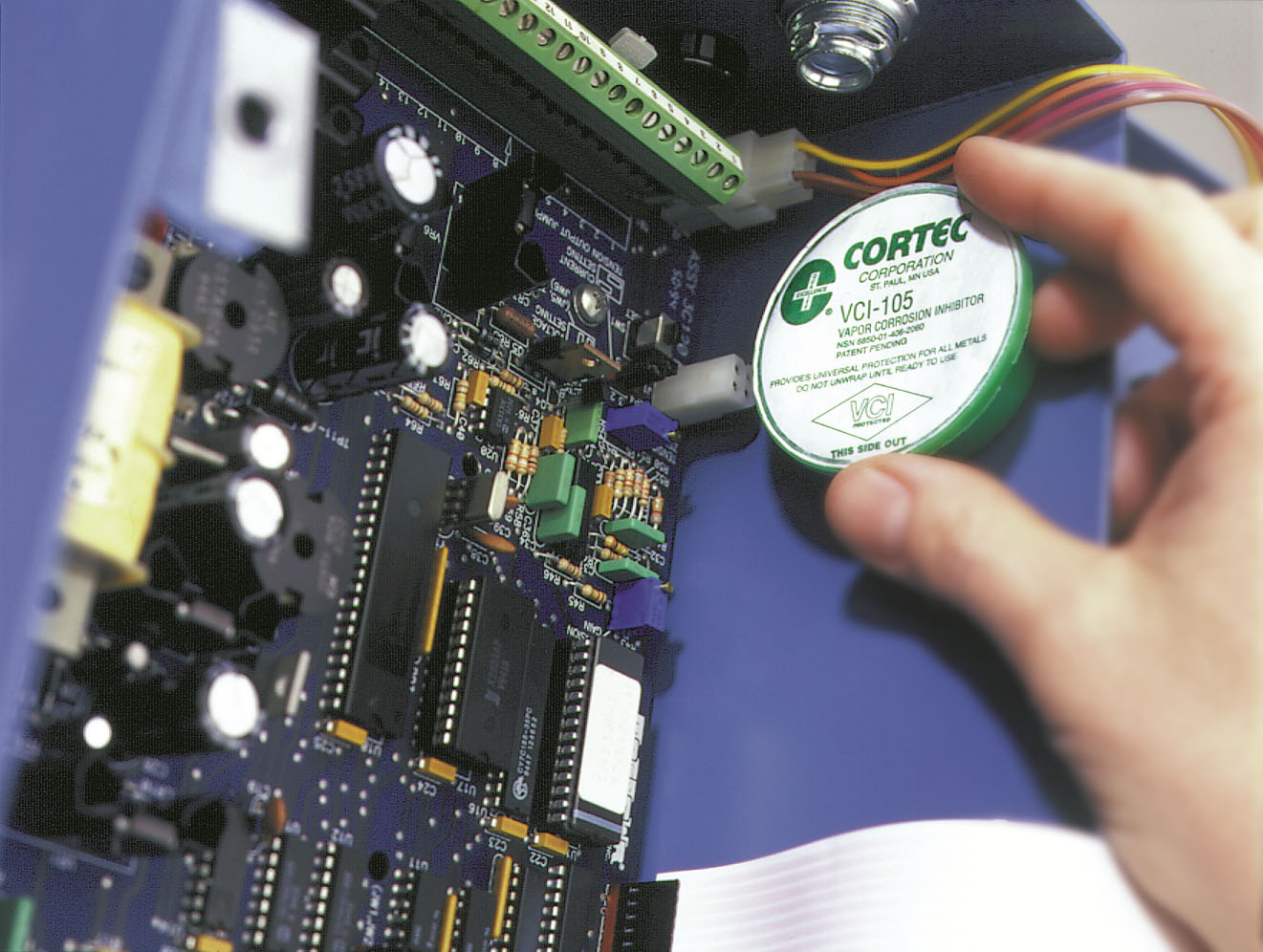

Asset Preservation

Corrosion is a threat to the integrity, value, and efficient operation of common industrial assets such as boilers, closed loops, and evaporative cooling water systems. Proper preservation of these assets during layup is

critical to ensuring long service life and smooth operations when bringing the equipment back online. Cortec’s

highly effective corrosion solutions help keep your assets in good condition while minimizing downtime and

labor costs.

Short-Term/Long-Term Layup

Whether your equipment will be offline for two weeks or two years, Cortec® offers outstanding layup strategies

for keeping your equipment corrosion-free and making it easy to bring back into operation. Many of Cortec’s

products contain Vapor phase Corrosion Inhibitors that offer multi-phase protection—forming a self-replenishing molecular barrier below the surface of the water, in void spaces above water, and at the air-water interface.

This allows the flexibility of protection in either dry or wet layup—for the long-term, on standby, and sometimes

even during operation.

Safer, Simpler Alternatives To Corrosion Prevention Under And Over Water Level

We offers a wide range of corrosion solutions that are much safer and/or simpler to use compared to

standard protection methods. You can replace the cumbersome use of desiccants

and avoid the hazards associated with nitrogen blanketing and hydrazine. With organic

corrosion inhibitors that are also generally easier to discharge into municipal wastewater systems than traditional

inorganic inhibitors that do not biodegrade. This water chemistry allows you to replace nitrites, molybdates,

phosphonates, and phosphates.

In any case we are always able to provide the best solution to you oil based rust prevention needs.

Our most popular VCI Oil, Oil additive and VCI Fuel Additives are the following ones:

VpCI®-329 is an oil-based vapor corrosion inhibiting concentrate

for use with lubricating, hydraulic, and preservation oils that provides outstanding protection in sheltered outdoor and indoor conditions.

VpCI®-329 Oil Base Volatile Corrosion Inhibitor protects in two unique ways by offering a film layer,

which clings to metal surfaces and also provides lots of vapor phase inhibitors into

the air above the oil level. The vapors condense and form a protective

barrier over the metal that is not in contact with the oil. This

combination allows complete protection to internals of machinery that remains idle.

VpCI®-329 is packaged in 5 gallon (19 liter) plastic pails, 55 gallon

(208 liter) metal drums, totes, and bulk.

The product should be

sealed before storage.

Agitate before each use.

VpCI®-707 - Volatile Corrosion Inhibitor Additive For Fuel (VCI Fuel Additive)

VpCI®-707 is a specially formulated fuel Volatile Corrosion Inhibitor additive designed to protect

fuel systems from corrosion and sludge formation during operation,

storage, or shipment. It effectively provides corrosion protection

in the fuel system not only in direct contact with the treated fuel,

but also in the vapor space above the fuel line. VpCI®-707 can

be effectively used as a fuel additive for day-to-day operation,

intermittent operation, preservation, and long term storage.

In-use gasoline or diesel tanks:

Add VpCI®-707 directly to gasoline or diesel fuel in blending,

storage, or vehicle tanks.

Dosage: 0.02 - 0.2% per volume of tank to be protected.

Storage and shipment of dry fuel tanks:

Fog VpCI®-707 concentrate into tank, covering as much internal

surface area as possible.

VpCI®-707 is available in 5 gallon (19 liter) pails, 55 gallon (208

liter) drums, liquid totes, and bulk.

Store closed in the original container at 40-100 °F (4.4-37.8 °C).

MCI® - Migratory Corrosion Inhibitors For Reinforced Concrete Structures

For more information and specs on MCI® visit our specific website

Migratory Corrosion Inhibitors are based on amine alcohols and amine carboxylates. They are classified as mixed inhibitors, meaning they provide both anodic and cathodic protection on a corrosion cell. MCI® is applied in many forms including as a concrete admixture or a topical treatment. It moves as a liquid through the concrete matrix via capillary action and migrates in a vapor phase throughout the concrete pore structure. When MCI® comes in contact with embedded metals, it has an ionic attraction to them and forms a protective molecular layer. This film prevents corrosive elements such as chlorides or carbon dioxide from further reacting with the reinforcement and also reduces existing corrosion rates, greatly extending concrete service life.

Increased durability will mean fewer repairs, greater structural integrity, and a longer service life, all leading to greater sustainability. MCI is made from a renewable raw material, enabling users to earn certain LEED credits. It is an excellent addition to building projects around the world seeking to meet sustainability standards such as the Estidama Pearl Rating System and BREEAM.

Cortec® Logo is registered trademark of Cortec® Corporation. VpCI®, MCI®, EcoClean®, EcoAir®, BioCorr® and Ecoline® are registered trademark of Cortec® Corporation